Message board -

These few solutions can help you effectively avoid risks!

Following are the top factors that you need to consider while choosing a plastic injection molding company

According to the current situation of China mould, how to identify reliable plastic injection molding companies, we can view and identify them from the following perspectives.

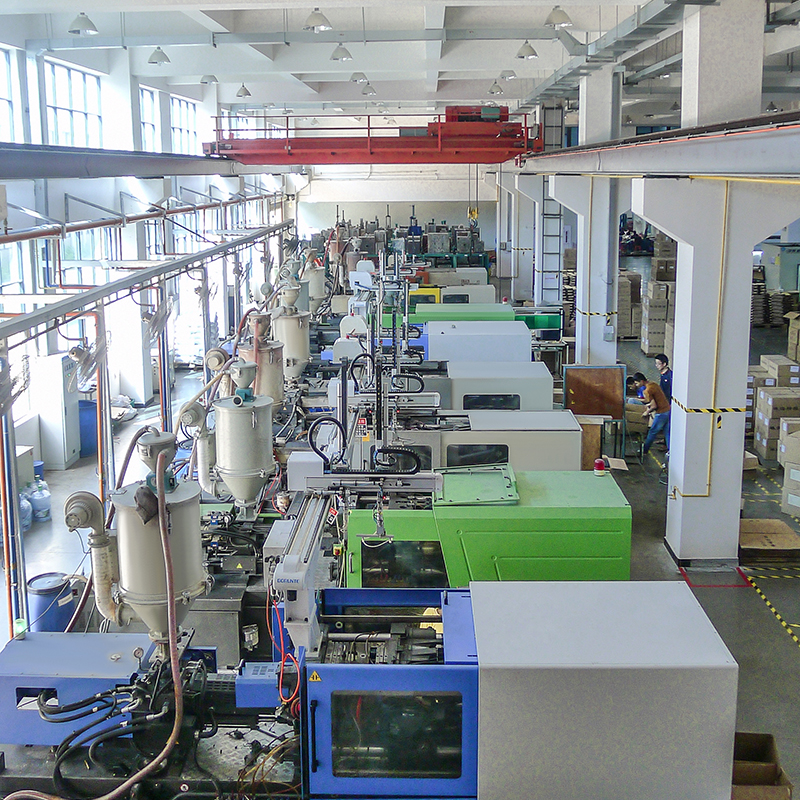

1. the scale of plastic mold factory

The injection mold (plastik enjeksiyon kalip)factory needs to have a certain production scale: to know whether the mold manufacturing equipment is high-tech equipment, and whether the management of the plastic mold factory is perfect. Choosing a plastic mold processing manufacturer has a certain operating time: the longer the operating time, the mold company will continue to have customer orders, which means that the mold quality, mold price, and company business philosophy have been recognized by customers, and a stable cooperative relationship can be established.

2. understand the product areas that the mold company is involved in:

For example, if you want to make products in the automotive industry, a manufacturer that has produced auto parts molds is more experienced and has less risk and error rate than a manufacturer that has never produced auto parts molds.

3. The supplier's injection mold production capacity and mold injection quality control ability

See how many precision parts the plastic mold factory can achieve. Only good molds can produce good products. The smaller the precision of a mold, the smaller the error. If your mold accuracy is required to be within 0.01mm, then the mold supplier should use slow wire wire cutting or EDM, or even in a constant temperature workshop to meet the requirements, and must have a certain accuracy of three coordinates and other tools for inspection. , to ensure the delivery of the mold. To understand the cooperation work, it is recommended to visit the site and start with small batch samples.![]()

4. Look at the supplier's production scheduling plan and quotation

Determine the cooperation, before signing the contract, ask the supplier to list the production cycle and time node of the plastic mold injection processing in detail, such as how much time it will take for the technical exchange and what to do. Whether the handover of each mold process is well connected.

In terms of quotation, it depends not only on the cooperative attitude of the supplier and the ability of cost control, but also on the reputation of the supplier in the industry, whether the cost of the newspaper is complete, and whether the price is objective, etc.

5. Look at the project management and control ability of the supplier

In the process of production, you must not relax, especially mold production is very important. You must inspect according to the project cycle and time point reported to you before. If there is any abnormality, immediately analyze, discuss and deal with it, and make remedial measures.

How to review, quote, inquire, purchase, follow up on delivery, etc. for mold suppliers, you can click https://www.zhjingmu.com/