Message board -

Zhuhai Jingmu Company has achieved another breakthrough in micro-precision injection molding, successfully manufacturing a highly challenging pin-matrix printhead guide plate component. Weighing only 0.05g, the product utilizes a 1-out, 4-cavity, multi-cavity precision mold, demonstrating exceptional production efficiency and stability.

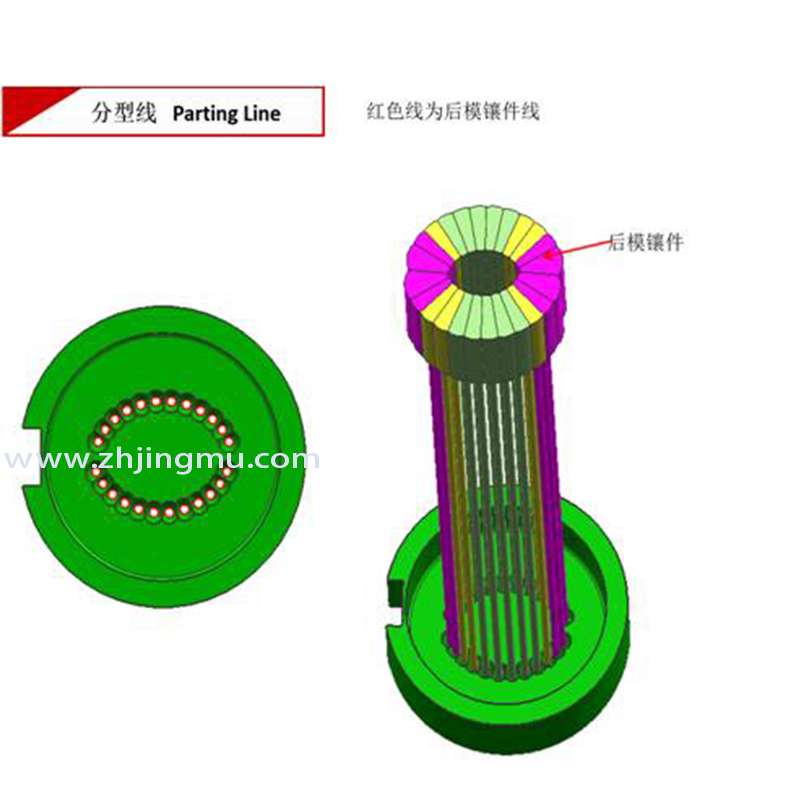

The technical challenge lies in the precise alignment and assembly of the 24 0.2mm guide pin holes in a circular arc, with each hole maintaining a strict tolerance of ±0.01mm. This not only requires extremely high mold machining precision, but also poses extreme challenges to the positioning and molding of the micro-pins. This success fully demonstrates Jingmu Company's leading technical expertise in micro-precision injection molding, micron-level tolerance control, and complex insert molding, providing a reliable model for the manufacturing of miniaturized components in high-end fields such as electronics and medical.

More Industry News

China Plastic Injection Molding Manufacturer

Injection Molding for Electrical Parts: Successful Sample Cases